Posted by Matt Delawder on

At SWD Inc., we specialize in providing world-class, customer-focused solutions, and our black oxide coating process is a testament to our commitment to quality and innovation. With extensive technical expertise, we consistently meet or exceed customer expectations, promoting employee growth, safety, and responsibility while also being a leader in environmental conservation and community stewardship. Here, we will explain the black oxide coating process, its applications, and why SWD Inc. is your trusted partner for this critical surface treatment.

What Is Black Oxide Coating?

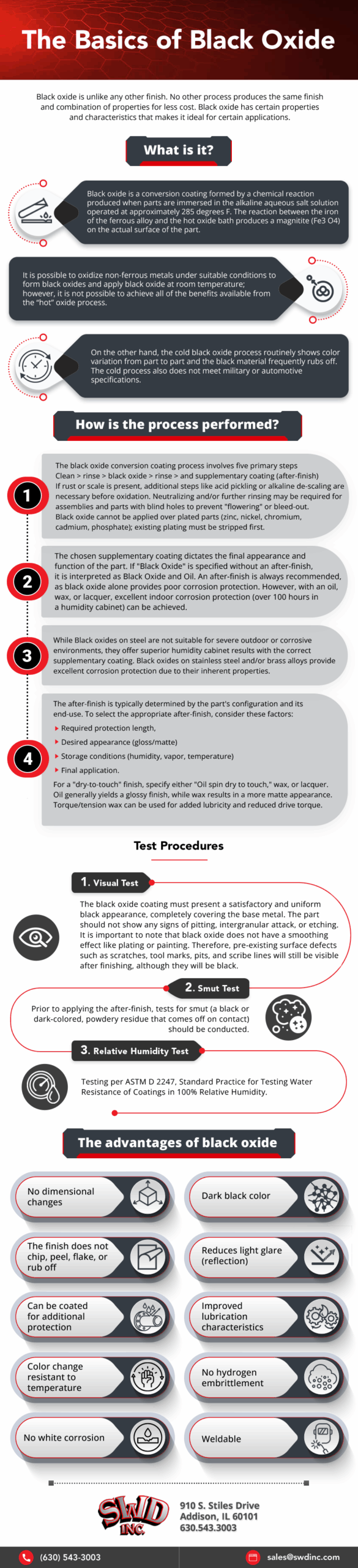

Black oxide coating is a chemical conversion process that blackens a part’s surface without applying a thick coating. It’s most commonly used for ferrous metals (metals containing iron), though it can also be applied to other metals like copper and stainless steel, which are specifically designed to resist surface reactions. Black oxide coatings are valued for their ability to increase corrosion and wear resistance while maintaining tight tolerance requirements.

There are several types of black oxide finishes:

- Hot black oxide

- Thermal black oxide

- Cool/Room-temperature black oxide

Hot Black oxide is particularly useful for parts requiring a degree of abrasion resistance, as the coating does not wear away easily.

Black Oxide Coating Process

The hot black oxide process involves several crucial steps, from preparation to the final after-finish.

Preparation and Cleaning Phases

The process begins with thorough cleaning to remove contaminants such as dirt, grease, dust, oils, and pre-existing rust from the parts’ surfaces. Depending on the material and its condition, acid etch-cleaning or an alkaline detergent may be used.

Conversion and Rinse Steps

Once cleaned, the parts are placed in a blackening solution containing the necessary oxidizing salts. This solution typically includes sodium hydroxide, nitrites, nitrates, and other chemicals. The bath is maintained at a steady temperature, usually between 285 °F and 305 °F. The chemicals react with the iron on the surface of the parts, producing magnetite (Fe3O4).

The extent of blackening is influenced by the immersion time (typically 5 to 40 minutes), the bath’s operational temperature, and the solution’s concentration. After treatment, the parts are removed from the salts and thoroughly neutralized.

Choosing an After-Finish: Oil, Wax, Lacquer

A critical step to enhance the coating’s durability and corrosion resistance is applying a sealing compound or oil to the coated metal. The resulting black oxide coating provides improved aesthetics, good corrosion resistance, and controlled surface albedo (level of reflectiveness). The black oxide finishing process is valued for its ability to maintain dimensional accuracy and conductivity while enhancing durability and scratch resistance.

Common Industry Applications

Black oxide coatings are compatible with carbon steel and stainless steel. This versatile finish is utilized across numerous industries:

- Automotive. Used for brackets, fasteners, brake components, wheel components, and trim.

- Aerospace. Found on brackets, fasteners, avionic components, landing gear components, and trim pieces.

- Electronics. Applied to contacts, connectors, enclosures, housings, and circuit board components.

- Hand tools. Enhances measurement gauges, dies, jigs, fixtures, and tool holders.

- Industrial. Commonly used for bolts, screws, washers, nuts, and threaded rods.

- Machine components. Applied to rollers, fasteners, gears, and shafts.

SWD Inc.: Experts in Black Oxide Coating

SWD Inc. has a strong reputation for reliability and providing top-quality products and services, including black oxide coating. Our expertise in this specialized process ensures that your components have a durable, high-performance finish that meets the most demanding specifications. With a commitment to world-class service and technical precision, SWD Inc. is the ideal partner for all your black oxide finishing needs.

To learn more about how SWD Inc. can help with your black oxide coating requirements, please request a quote today.