Posted by Matt Delawder on

SWD Inc. offers industry-leading black oxide coating services designed to improve both performance and aesthetics across a wide range of components and industries. As a trusted provider of surface finishing solutions for over four decades, SWD brings unmatched expertise and precision to every project.

At SWD, our mission is to provide world-class, customer-focused, sustainable, and socially responsible solutions. That commitment is backed by:

- A culture of service, quality, and innovation

- Technical expertise that supports demanding applications

- A dedication to exceeding customer expectations

- An emphasis on employee safety, development, and shared success

- A focus on community stewardship and environmental conservation

- This is all something we call “Better4”

We are proud to be recognized as the largest black oxide plating operation in the continental United States.

What Is Black Oxide Coating?

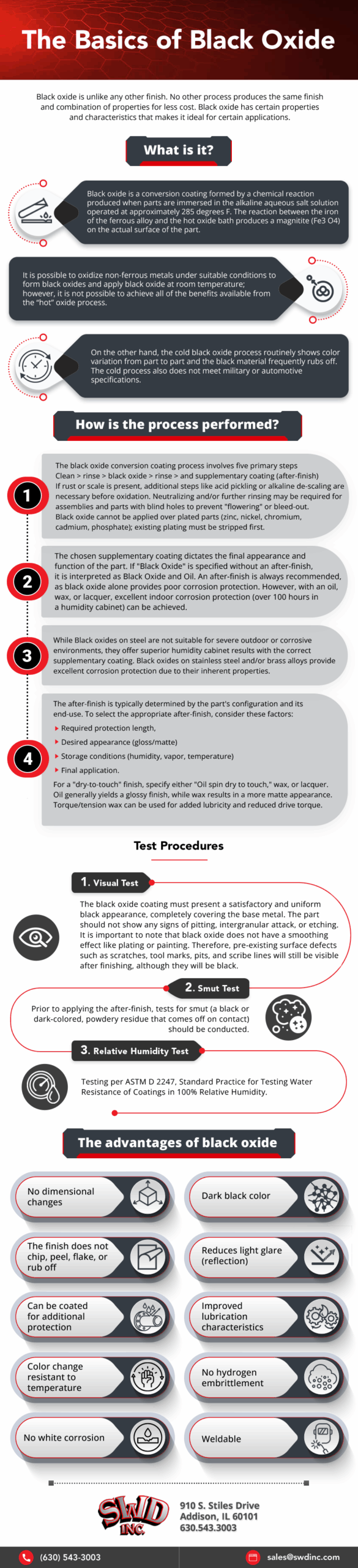

Black oxide coating is a chemical conversion process that forms a black magnetite (Fe₃O₄) layer on the surface of ferrous metals. This finish is achieved by immersing parts in an alkaline salt solution heated to approximately 285 °F. The result is a uniform black surface that adds mild corrosion resistance without affecting part dimensions.

The process includes several stages: cleaning, rinsing, the black oxide bath, another rinse, and then a supplementary coating, often referred to as an “after-finish.” Depending on the chosen after-finish, parts may appear shiny or matte, retain polished surfaces, and gain additional corrosion and wear resistance.

Additionally, black oxide finishes will not chip, flake, or peel. The coating becomes an integral part of the metal, and it can only be removed by abrasive or chemical means. However, the process is only effective on bare metals; plated components must be stripped before treatment.

Common after-finishes include oil, wax, and lacquer, which are chosen based on the desired appearance, lubrication properties, and protective qualities.

Key Advantages of Black Oxide Coating

Compared to other metal finishing processes, black oxide plating offers several key advantages:

- No dimensional change. The black oxide process does not add or remove material, preserving tight tolerances.

- Durable dark finish. The deep black color does not fade or develop a rainbow-like patina. The original surface texture (whether polished or matte) remains visible and consistent.

- Non-peeling surface. Because black oxide becomes part of the base material, it won’t chip or rub off during use.

- Reduced glare. The matte finish minimizes light reflection, making black oxide ideal for tools and components in high-visibility or fatigue-sensitive environments.

- Supplementary protection. Oil, wax, or lacquer finishes can improve corrosion and abrasion resistance.

- Enhanced lubricity. Treated parts exhibit anti-galling properties and smooth performance in mating assemblies.

- High heat resistance. Black oxide finishes can withstand up to 900 °F (482 °C) before discoloration occurs.

- No hydrogen embrittlement. The process does not involve acid activation or electroplating, making it suitable for high-stress applications.

- Weld-friendly. Black oxidized components can be welded without toxic fumes or bonding issues.

These benefits make black oxide a versatile and cost-effective finish for manufacturers who need durability without sacrificing appearance.

Ideal Industry Applications

SWD’s black oxide coating services support a broad range of industrial and commercial needs. The process is suitable for iron-based metals, including carbon steel and cast iron, as well as stainless steel.

Common applications include:

- Firearms

- Gears

- Pins

- Fasteners

- Hand tools

- Fixturing

- Molds

- Tooling components

Whether you’re producing precision mechanical parts or high-use hardware, SWD can tailor the process and finish to suit your performance and aesthetic requirements.

Black Oxide Coating Services from SWD Inc.

With over 45 years of experience and one of the most advanced metal finishing facilities in the country, SWD Inc. is a premier provider of black oxide coating services. Our black oxide capabilities are backed by ISO 9001:2015, ISO 14001:2015, and ISO 17025 certifications, ensuring consistent quality and regulatory compliance.

Clients across industries trust us for our attention to detail, quick turnaround times, and customer-first approach. From engineering consultation to final finishing, our team works collaboratively to deliver results that meet the highest standards.

For more information about our black oxide coating services, or to get started on your next project, request a quote today.