Pickling is a cleaning process that helps prepare parts and materials for different operations during the manufacturing process. Items made of brass, such as ammunition casings and fasteners like screws or brackets are often picked at different stages of manufacturing because pickling cleans them effectively after drawing or annealing, and prior to any machining or plating operations.

At SWD, Inc. we offer pickling along with our other cleaning, stripping, plating, and passivation services. Here, we’ll look at what pickling is, ways it is used in manufacturing, and how our pickling capabilities improve manufacturing quality and the appearance of brass products.

What is Brass Pickling?

Brass pickling is the process of applying brass items in an chemical bath, also called pickle liquor, that reacts with the surface of the metal. Depending on the application, sulfuric, nitric, citric, or other acid solutions may be used.

The acid dissolves oils, oxides, lubricants, and other contaminants that accumulate during stamping, drawing, annealing, and other operations. Pickling is usually followed by thorough drying, plating, or a light coating with oil to prevent oxidation or corrosion.

Brass pickling begins with pre-cleaning of the parts, enabling the pickling solution to come into more direct contact with the brass. The parts are submerged in the chemical bath, which dissolves surface oils, lubricants, and other impurities. This is followed by rinsing, often with inhibitors to further mitigate the risk of an adverse reaction during rinsing. Then the parts are neutralized with an alkaline solution that creates a stable surface. Parts are then ready for additional finishing processes.

Industry Applications

Pickling is used in several different manufacturing processes to prepare brass items for plating, heat treating, or to create a uniform, golden finish, such as:

Cleaning bullet casings after drawing or heat treating.

Dissolving oils and lubricants used during machining or stamping of fasteners.

Preparing components for CNC machining operations.

Preparing brass surfaces for aesthetic finishes in decorative applications.

Removing contaminants and enhancing the corrosion resistance of plumbing and construction components.

Activating surfaces for electrical connectors and terminals during plating.

Creating a clear and uniform finish on brass musical instruments.

Surface preparation for gears, bushings, and other mechanical components.

SWD’s Brass Pickling Capabilities

SWD offers reliable pickling solutions for brass fasteners, ammunition, and other brass items. Pickling removes contaminants, residues, oils, and other foreign material from brass components, which may interfere with machining, plating, or other finishing processes. When appropriate, we also apply a light coating of oil to prevent corrosion or oxidation.

We are also ISO 9001:2015- and ISO 14001:2015-certified, and use computer-controlled, precision immersion processes for repeatable, consistent results batch after batch.

Brass Pickling Services From SWD, Inc.

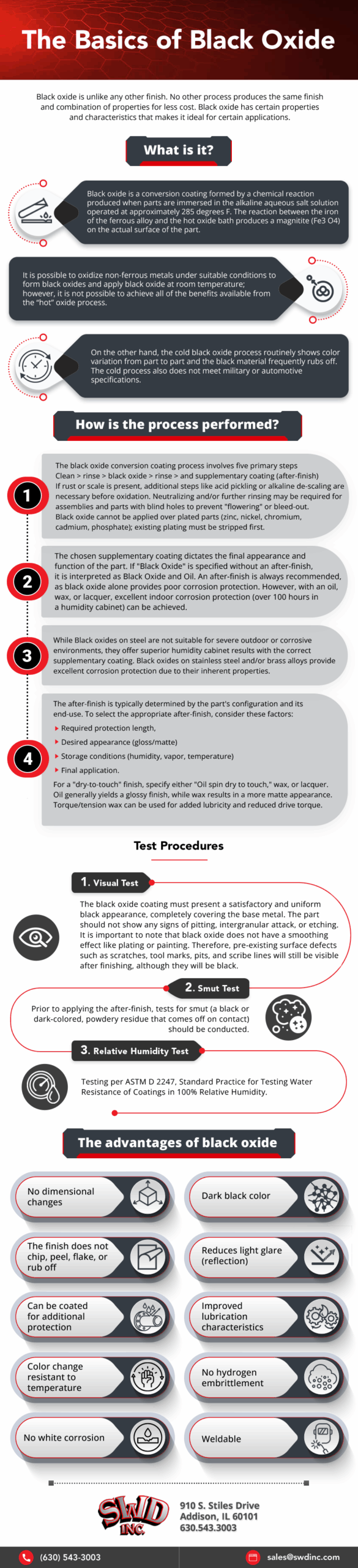

Since 1980, SWD, Inc. has offered high-quality metal finishing services for customers in the Chicago area and beyond. We also offer cleaning, stripping, iridescent wax applications, stainless steel passivation, and several plating finishes like black oxide, zinc-phosphate, and manganese-phosphate.

Contact our team to learn more about our capabilities, or request a quote for your next order!